Different Types of Sensors – Analog and Digital

Sensors have become an integral part of the embedded system. Right from your mobile to security systems installed at home. They are also becoming important for meteorological stations to predict weather parameters like temperature, pressure, humidity, and many more.

To interface any sensor to the microcontroller, you have to know the function of the sensor and different types of sensors used in remote sensing, weather systems, security devices, health equipment etc. But, before going to know about sensors and its types you must know the basic definition of the sensor and its use.

What is a Sensor and How does it Work?

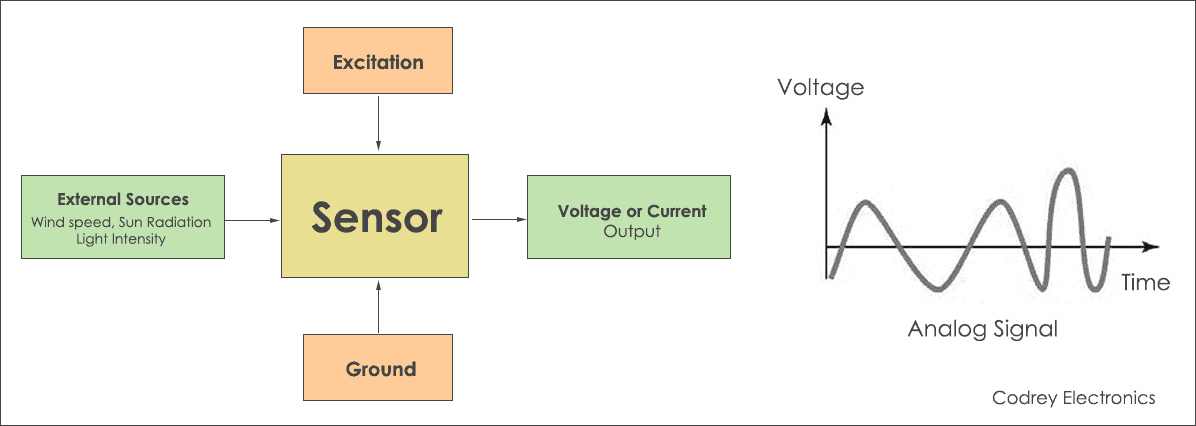

Sensor – Block Diagram

Sensor is a module or chip that observes the changes happening in the physical world and sends the feedback to the microcontroller or microprocessor. Excitation (Power supply) and Grounding must be provided to the sensor for the proper working.

Classification of Sensors

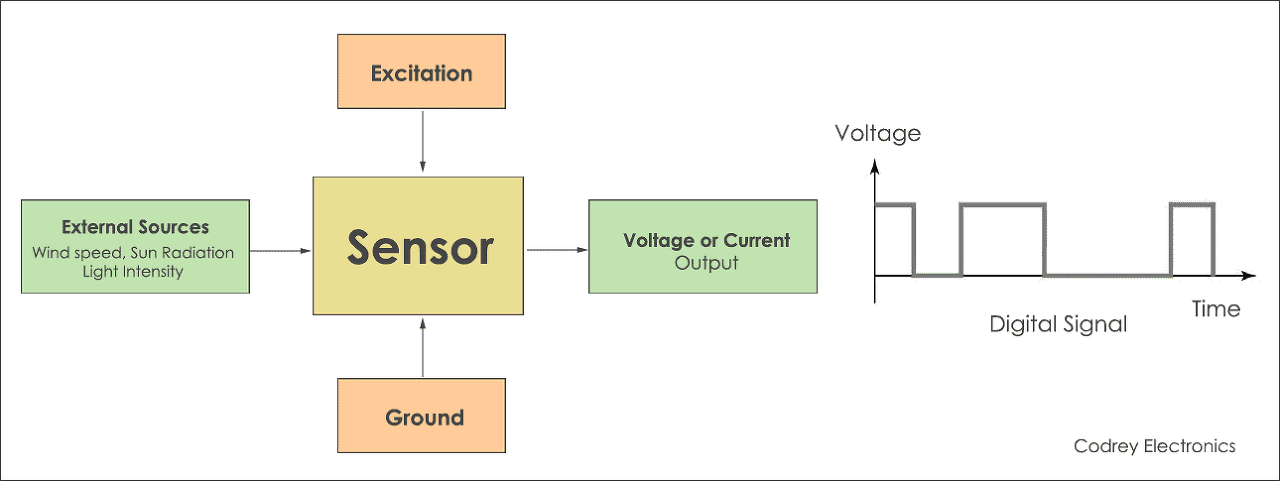

Microcontroller accepts two types of inputs depending up on the type of sensor i.e. analog or digital.

Analog sensor senses the external parameters (wind speed, solar radiation, light intensity etc.) and gives analog voltage as an output. The output voltage may be in the range of 0 to 5V. Logic High is treated as “1” (3.5 to 5V) and Logic Low is indicated by “0” (0 to 3.5 V).

Analog Sensor – Block Diagram

Unlike analog sensor, Digital Sensor produce discrete values (0 and 1’s). Discrete values often called digital (binary) signals in digital communication.

Digital Sensor – Block Diagram

Sensor Selection [Analog or Digital]

To select a sensor it’s important to know about analog and digital circuits. Analog circuits are made up of analog components like resistor, capacitor, Operational amplifiers, diodes and transistors.

Whereas digital circuits consist of logic gates and microcontroller chips. Analog signals are much affected by external noise and create errors in the output signal. But digital signals are susceptible to noisy environments and hence digital sensors are preferred over analog ones.

Note: If your application needs better accuracy and throughput go for digital sensors.

Problem with digital sensors:

Digital sensors have low calculation range. For example, digital temperature sensors such as HYT 271 and SHT series have lower temperature range.

But analog temperature sensors (RTD) have higher resolution (positive and negative temperature). This feature makes analog sensors suitable for wide temperature range and stability. The analog output from the sensor is processed by the ADC (Analog to Digital Converter) of the microcontroller.

As discussed above, how sensors are classified and how to select a sensor, now it’s time to know about different sensors in nature and how they are used in the industrial applications.

Types of Sensors

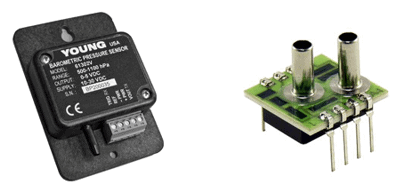

1. Analog Pressure Sensor

Analog Pressure sensors work on the input voltage and against the known pressure value. The output of pressure sensor is analog output voltage (normalized). The units of pressure are psi (pounds per square inch).

Analog pressure Sensors (Barometric)

2. Digital Pressure Sensor

Digital pressure sensor has inbuilt signal processing unit such as ADC that converts the analog input to digital pressure output. Generally, in most of the digital sensors I2c based digital signals are taken out.

Some of the applications of the Barometric pressure sensor are:

- Leak detection in gas pipes and cables

- Measuring pressure for environmental purpose

- Radiosonde

- Tyre pressure monitoring

- Respiration analytics

- Industrial and process control

- Medical devices

- Airflow monitoring

- Drones

- Inhalers

- Water level measurement

3. Analog Hall effect/Magnetic Sensor (Position Sensor)

The Hall Effect sensor works on the magnetic field. It senses the magnetic field and gives the output voltage. When the magnetic field is positive output voltage increases above the null voltage (no magnetic field and zero current).

Applications of Hall sensor are:

- GPS positioning

- Current sensing

- Speed movement detection

- Magnetic code decoder

- Metal detector

- Controlling motors

4. Load cell (weighing sensors)

Load cells measures and process the weight. There are different types of load cell sensors based on usage of the application. Some of them are:

- Beam Load cells (Bending Load cell)

These are suited for normal weight measurement applications and industrial-weight measurement. Applications of beam load cell are

- To fill the machinery

- Tank weighing

- Vehicle Onboard weight

- Medical equipment

- Bed weighing

- To package machinery

- Single point Load cell

Single point load cells are used for low weight systems.

Applications:

- Bench and retail scaling

- Waste collection

- Package and filling machinery

- Compression Load cell

These are suitable for high weight scaling systems.

Applications:

- Medical devices

- Measuring equipment

- Pump controlling devices

- Railway weight checkers

5. Temperature Sensor

Analog temperature sensor measures the temperature of the current location based on the resistance in variation. The value of resistance changes with temperature.

RTD sensors are best suitable for stability, accuracy and reliability. They comes with wide temperature range.

Applications:

- To measure water temperature

- Air temperature measurement

- Air conditioning

- Plastics

- Food processing

6. Reflex Sensor

A simple reflex sensor has transmitter and receiver sections. The transmitter sensor emits a light beam and when an object is detected the receiver captures and process this as changeover signal.

Applications:

- Monitors flow of material process

- Level measurement

- Print and Color detection

- Inspection of Assembly

- Sealing cap monitoring

- Recording level of liquid quantities

7. Fork Sensor

Fork sensors are quite close to the reflex sensor but efficient in picking and detecting very small objects with a size of micrometers (µm).

Applications:

- Bonding control

- Placing and sorting small components

- Power supply control

- Gap monitoring and control

- Recognize holes and drills

8. Wind speed / Wind direction Sensor

Wind speed/wind direction sensor commonly called anemometer uses the ultrasonic technique to get wind speed and direction.

Applications:

- Environmental weather stations

- Drifter Buoys

- Oceanographic and meteorological stations

- Harbours and seaports

- Road tunnels

9. Radar Sensor

Radar transmit short microwave signals that travel at the light speed. Radar sensors are used for measurement of liquid levels. The output analog current (4-20 mA). This current is converted to the voltage by placing a resistor and read by the ADC of a microcontroller.

10. Solar Radiation Sensor

Global radiation sensor (solar radiation) uses photo voltaic diode for measuring solar radiation.

Applications:

- Meteorological stations

- Hydrological and agriculture

- Energy applications

- Irrigation

11. Humidity Sensor

Humidity sensor calculates the humidity of the present location. Humidity is an important parameter for environmental observance, consumer electronics and medical diagnostics.

Applications:

- Humidity transmitter

- Handheld devices

- Refrigerators

- Air compressors

- Weather stations

- Industrial incubators

- Medical systems

- Dew measurement

12. Air Quality Sensor [Gas sensor]

This sensor monitors the number of gases in the air like CO2 (carbon dioxide), SO2 (sulfur dioxide), CO (carbon monoxide) etc.

Applications:

- Meteorological institutes

- Health agencies

- Homes and Hospitals

- Industrial applications

- Ventilation systems

- Air cleaning

13. Light Sensor

Light sensor captures the ambient light (dark/bright) and converts it to current.

Applications:

- Display backlight in Mobiles and LCDs

- PDA (Personal digital assistant)

- TVs, Cameras

- Toys

- Automatic street light control

- CCTVs

14. Rainfall Sensor

Meteorological agencies use rain gauge sensor to measure the amount of rainfall falls in a particular location. Rainfall is measured in mm. The most used device for measuring rainfall is Tipping bucket Rain gauge.

15. Soil Moisture Sensor

Soil moisture measures the amount of salt and moisture in the soils. It also measures the temperature in the soil. It is based on SDI-12 protocol.

16. Water Level Sensor

Water level sensor calculates the depth of water in lakes, dams and rivers. There are various analog and digital based water level sensors.

Applications:

- Water level monitoring

- Environmental applications

- Groundwater tanks

- Surface water applications

Conclusion

Sensors have become a vital part of consumer electronics, industrial electronics, Robotics and Internet of things. I hope this article gives you an overview of different types of sensors used in the industry.

산업 모니터링에 관한 다른 Contents도 확인 하세요.

'ForBeginner' 카테고리의 다른 글

| 2-0. 왜 Sensor의 이해가 필요한가? (0) | 2021.05.19 |

|---|---|

| 2-4. 센서와 변환기 (0) | 2021.05.19 |

| 2-2. Types of Sensors (0) | 2021.05.18 |

| 8-7. MSSQL(View) (0) | 2021.05.18 |

| 8-5. 트리거(Trigger) (0) | 2021.05.18 |